Martin

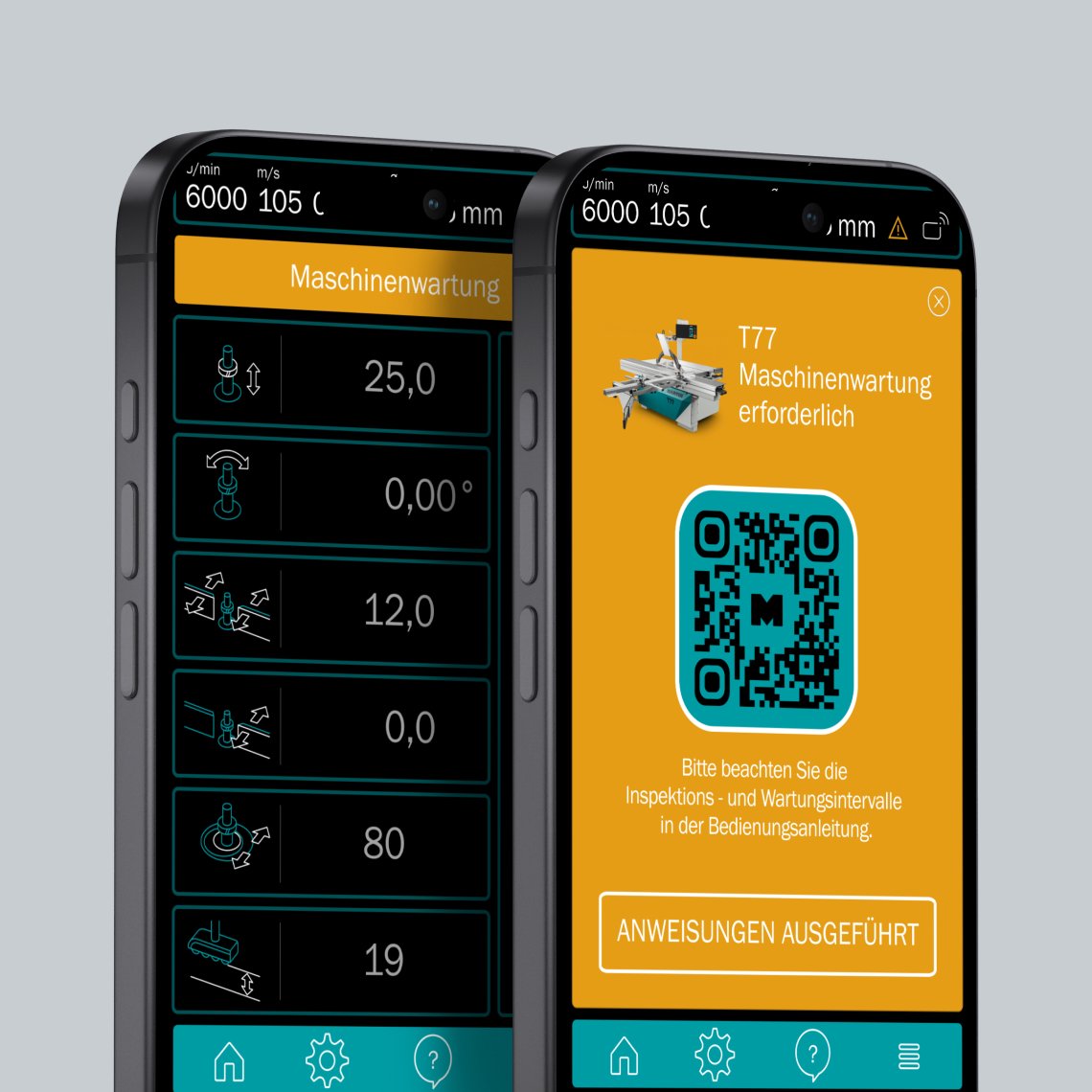

PLC SOFTWARE DEVELOPMENT

Client

Otto Martin Maschinenbau GmbH & Co.

Industry

Power Tools Industry

Team size

3-6

Time frame

1 year

Technology used

Otto Martin Maschinenbau GmbH & Co.

Power Tools Industry

3-6

1 year

HOW WE MADE IT WORK

The solution relied on fast onboarding, strong Product Owner involvement, and close team collaboration. Tasks were distributed flexibly, knowledge was shared continuously, and numerous bugs, unfinished tasks, and new features including entirely new modules were successfully delivered, leading to the launch of a new machine generation.

The outcome was a stable, production-ready control software foundation that supported the successful launch of Otto Martin’s new machine generation and enabled future extensibility through modern connectivity.

Quickly adapting from object-oriented development to a PLC environment and new programming paradigms.

Seamlessly extending an existing team with the right mix of roles, scaling expertise and capacity as project needs evolved over time.

Working effectively across development, product, and UI/UX roles while supporting internal and external stakeholders.

Ability to work remotely when needed, while also presenting, testing, and aligning directly onsite with engineers and stakeholders on real machines.